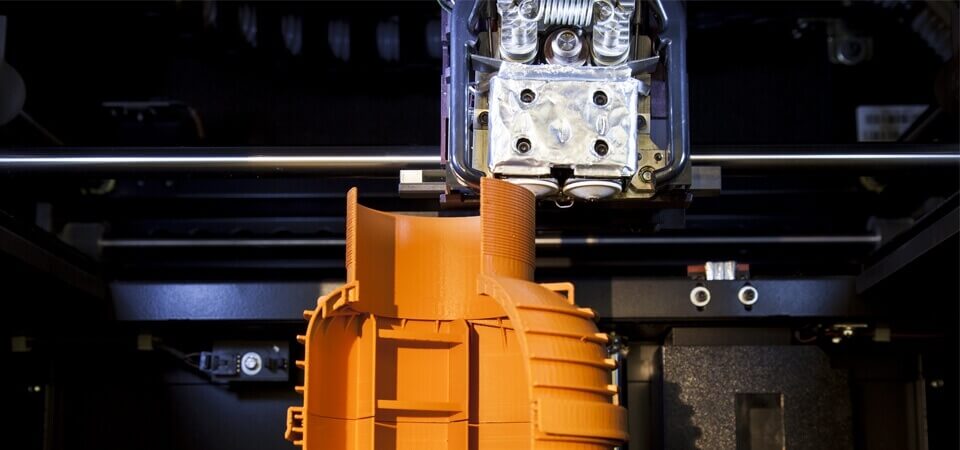

Components are produced by 3D printing to test their functionality in advance. This allows assembly operations to be verified and simple function tests to be conducted.

Thanks to production of an actual component, decisions can be made in advance as to how this component needs to be changed for it to fulfil its function in practice.

To gain initial insights into the function of tool elements, various tool components are also produced by 3D printing in order to test the motion sequences as quickly as possible for their functionality.

ifw offers the production of components by 3D printing as a service. Elements with dimensions of up to 254 x 254 x 305 mm can be printed in an FDM process. Different colours of ABS material are available for this purpose.