Alongside production of injection moulds, ifw can provide all the necessary product development and product design for injection-moulded components. The component requirements are compiled in consultation with the customer.

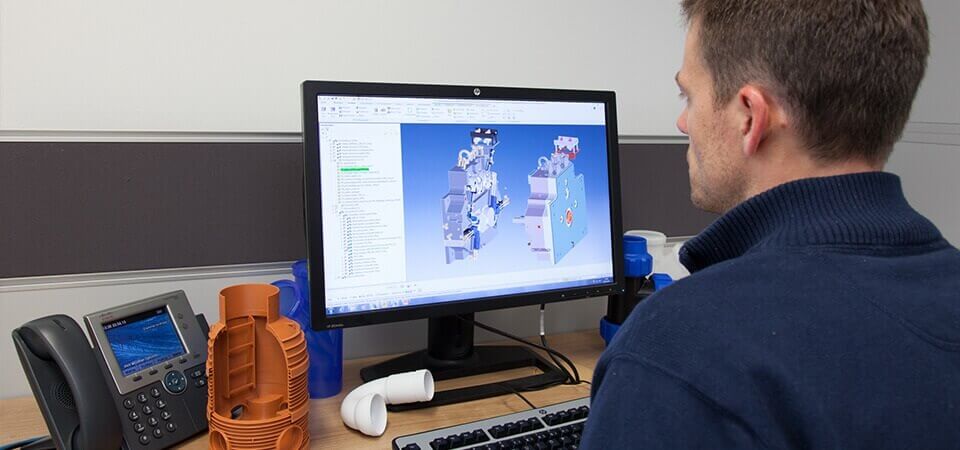

ifw takes responsibility for the entire component development process through to first series production. This ensures product design suitable for plastics. Material accumulation and the consequent unnecessary increase in cycle time can be avoided. Optimum component filling is verified by means of Moldflow simulation. Component function can be checked on prototypes produced with our in-house 3D printer.

However, ifw can also assist in selecting the injection-moulding materials. Very much experience in the processing of materials in our lab and ifw kunststofftechnik and close cooperation with the material manufacturers, ensures the correct selection of plastics.

Even when the customer specifies geometries, ifw checks whether component optimisations are possible. While maintaining component functionality, the cost-effectiveness of production can often be significantly improved by the slightest of changes. The resulting savings over the entire mould service life can be huge.